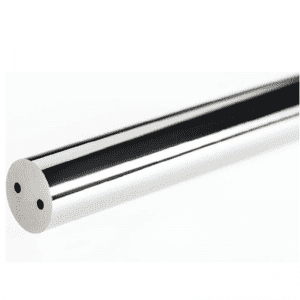

Volframa cietā karbīda stieņi gala frēzēm un urbjiem ar stabilu augstu kvalitāti

1. Volframa cietā karbīda stieņi tiek presēti formējot vai presējot.

2. Volframa cietā karbīda stieņus saķepina ar zema spiediena integrētu saķepināšanas krāsni, tāpēc kopējā veiktspēja ir augsta.

3. Neapstrādāto volframa-kobalta karbīda apaļo stieni vai apaļā stieņa ārējo diametru var uzlabot un pulēt atbilstoši jebkurai pielaidei. Kopējās pielaides ir h5, h6, -0,005 utt., un var apstrādāt arī karbīda stieņu gala slīpumu.

4. Karbīda stieņi ir piemēroti vispārēja tērauda, čuguna, nerūsējošā tērauda, karstumizturīga tērauda, niķeļa bāzes un titāna sakausējuma apstrādei. Ieteicams vispārēja lietojuma karbīda instrumentu materiāliem, piemēram, vītņurbjiem, gala frēzēm, krāniem un urbjmašīnām.

Mūsu karbīda stieņu veidi

1.Neslīpēti garie stieņi

| TOL. of Unground Long stieņi | ||

| Izmērs (DxL,mm) | Tolerance | |

| D(mm) | L(mm) | |

| D[1-3)x310/330 | 0,30 ~ 0,55 | 0,00~+4,00 |

| D[3-12)x310/330 | 0,30 ~ 0,60 | 0,00~+4,00 |

| D[12-20)x310/330 | 0,30 ~ 0,65 | 0,00~+4,00 |

| D[20-40]x310/330 | 0,30–0,70 | 0,00~+4,00 |

2.Neslīpēti pēc garuma nogriezti stieņi

| TOL. nenoslīpēti pēc garuma stieņi | ||

| D/L(mm) | D&L TOL.mm | |

| L<=70 | 70<L<=150 | |

| D<5 | D(0.20~0.30), L(0.20~1.5) | D(0.25~0.35), L(0.20~1.5) |

| 5<=D<40 | D(0.25~0.35), L(0.20~1.5) | D(0.30~0.40), L(0.20~1.5) |

3.Ground long rods

The tolerance of the long rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+5.00mm in Length as normal.

4.Ground cut-to-length rods

The tolerance of the ground cut-to-length rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+2.00mm in Length as normal.

5.PCB Rods

more than 50 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

1.Tungsten carbide blanks production

Good quality carbide products rely on 100% virgin raw materials and advanced wet-milling,pressing machines and sintering furnaces. We put emphasize on every production process of our carbide blanks. To keep good quality of carbide blanks is the base of furtherly machined high precision finished carbide parts.

2.Inspection and testing process

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

NCC owns a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.